YANMAR IMPELLERS

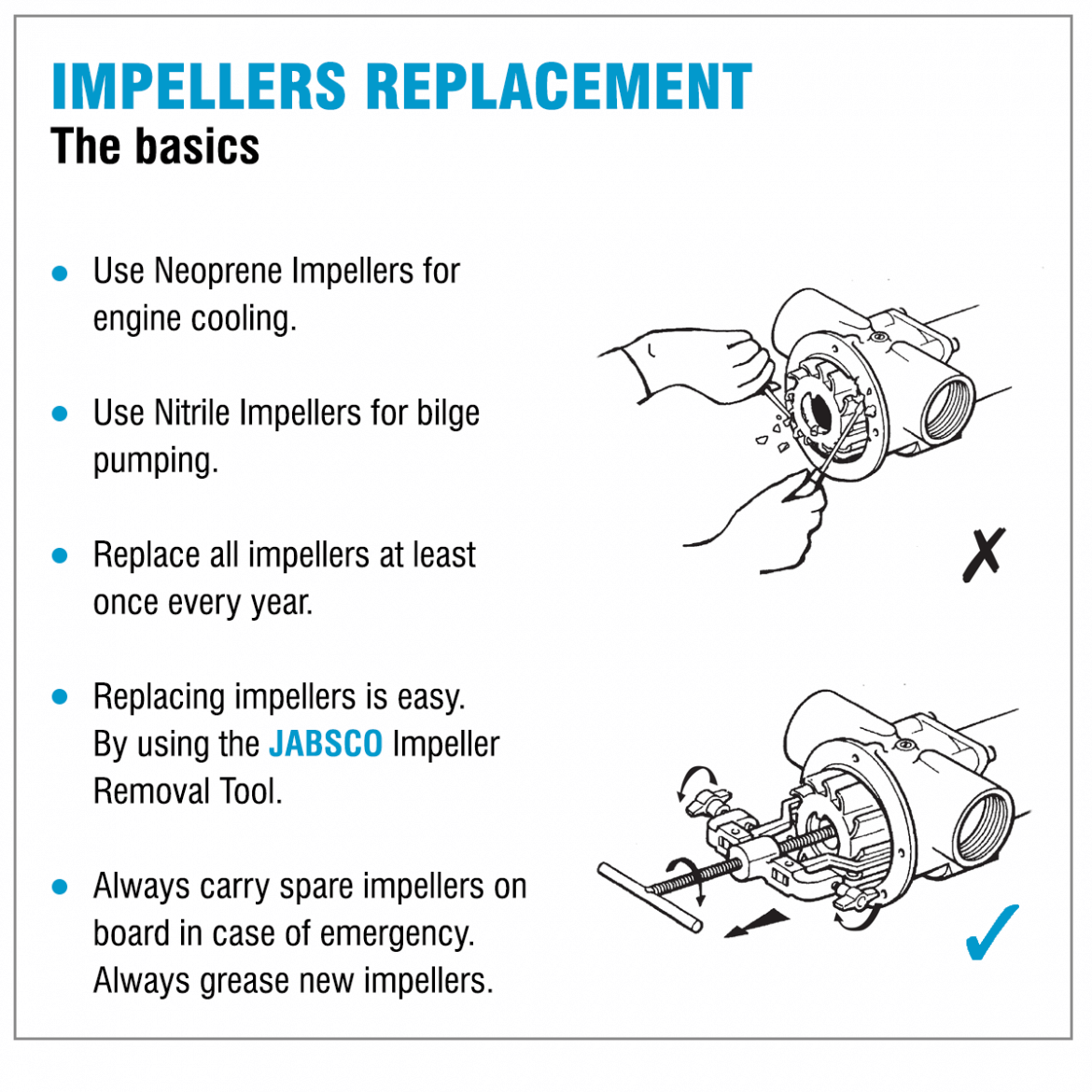

Changing an impeller is not a daunting task and it’s one that every boater should consider adding to their arsenal of DIY maintenance. Changing an impeller, on many engines, usually takes less than 20 minutes even if you are fairly slow. The most complicated aspect of the task is physical access to the pump.

Step 1: Loosen the screws and remove them. If they are frozen or rusted use some PB Blaster but be very, very careful not to just blast it everywhere. Please understand that PB Blaster can eat pump seals, engine seals and engine gaskets for breakfast. If you need to use a penetrating oil I’d advise spraying it into the spray can cap and then dab it on the screws with a Q-Tip.

Step 2: Pry the cover plate off. I use a knife blade for this and it works fine. There are many ways to get the plate off but what ever method you choose make certain it does not harm the gasket mating surfaces.

The face plate of a water pump is considered another wear item. If it’s scored and worn you should replace it or flip it.

Some pumps, such as certain Oberdorfer models, have cover plates with no stamped part numbers on them. If your cover plate is worn, and the opposite side has no paint or stamping marks, you can simply flip it around and re-use it.

Clean the Cover Plate

Before re-using the cover plate you should clean it and make the gasket surface smooth again. To do this I simply use Scotch-Brite pads. Be sure to remove all traces of the previous gasket from both the pump body face and the cover plates mating face. Being diligent in your cleaning duties will minimize the potential for a gasket leak.

Sierra Impellers

Are a Great solution for outboard engines. Suitable for Yamaha, Mercury, Suzuki and Honda.

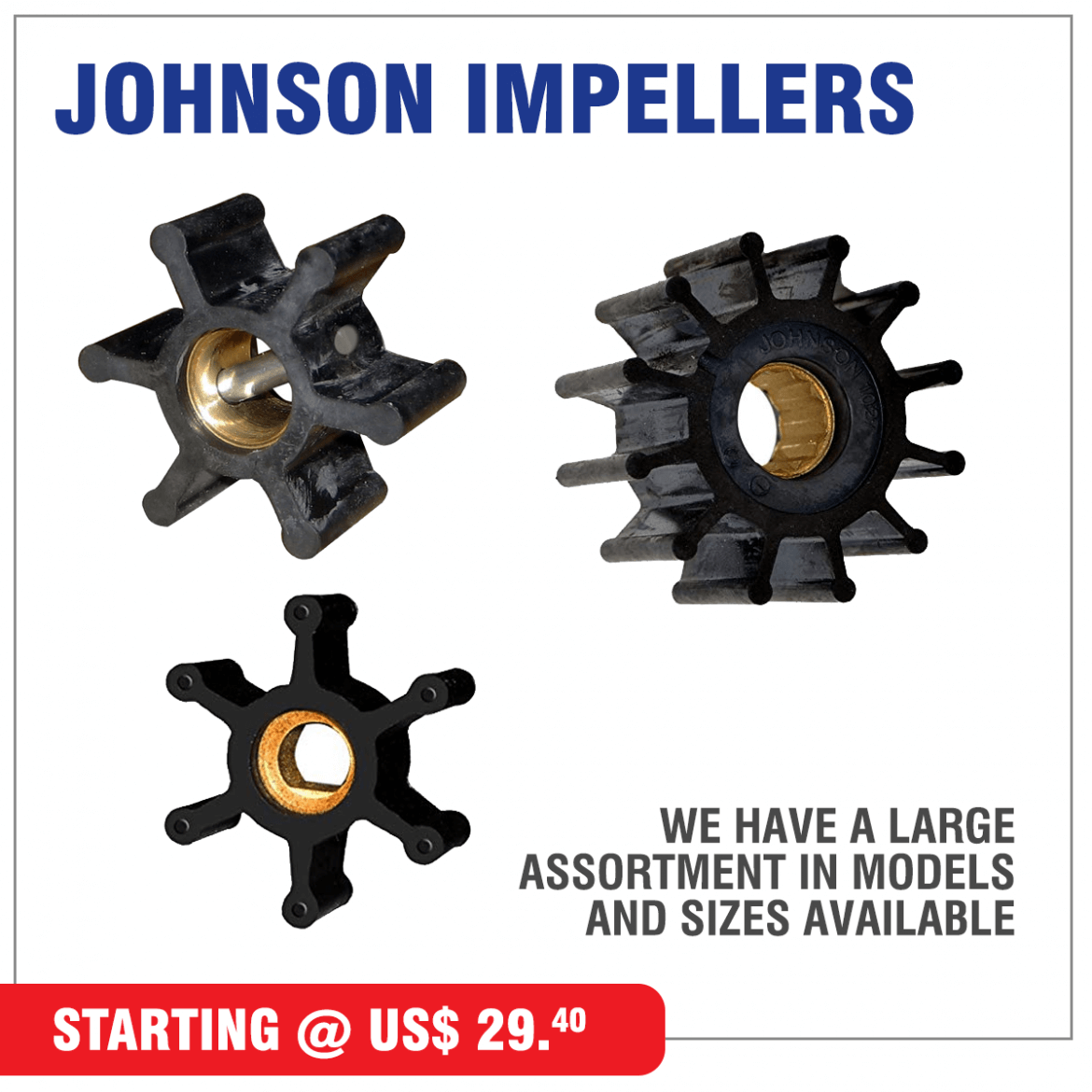

JOHNSON PUMPS

Benefits with flexible impellers from Johnson Pump® www.spxflow.com

- Stable pressure delivery over time

- Significantly longer service life

- Excellent self-priming capability

- Minimized swelling

- Minimized failures due to fatigue

- Correct impeller dimensions

- Correct cooling flow & sufficient cooling directly at start up

Strum boxes are used to filter water and liquids using a debris gauze. This is particularly useful for the bilge area of your boat, to prevent bits and pieces getting into your bilge pump and causing damage to the inner components. Some of these strum boxes are available with an integrated non-return valve to help the pump with priming.