Virtually all boats end up with unwanted water in the bilge – from a propeller shaft packing gland, a leaky portlight, seams in a wooden boat, and other sources.

Water left in the bilge can cause spilled fuel to slosh around and attack insulation on electrical wiring. It also promotes osmotic blisters in fiberglass hulls and can destabilize and even sink a boat. Luckily there are products to prevent this from happening.

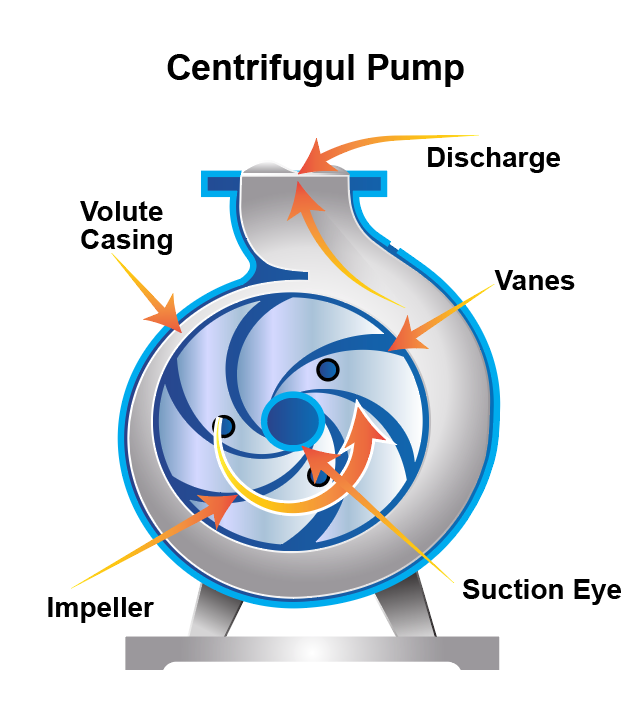

Centrifugal Bilge Pumps have high pumping power and can move lots of water. They are low maintenance and can withstand small amounts of debris without clogging. They are not self-priming, so must be installed where they won’t run dry.

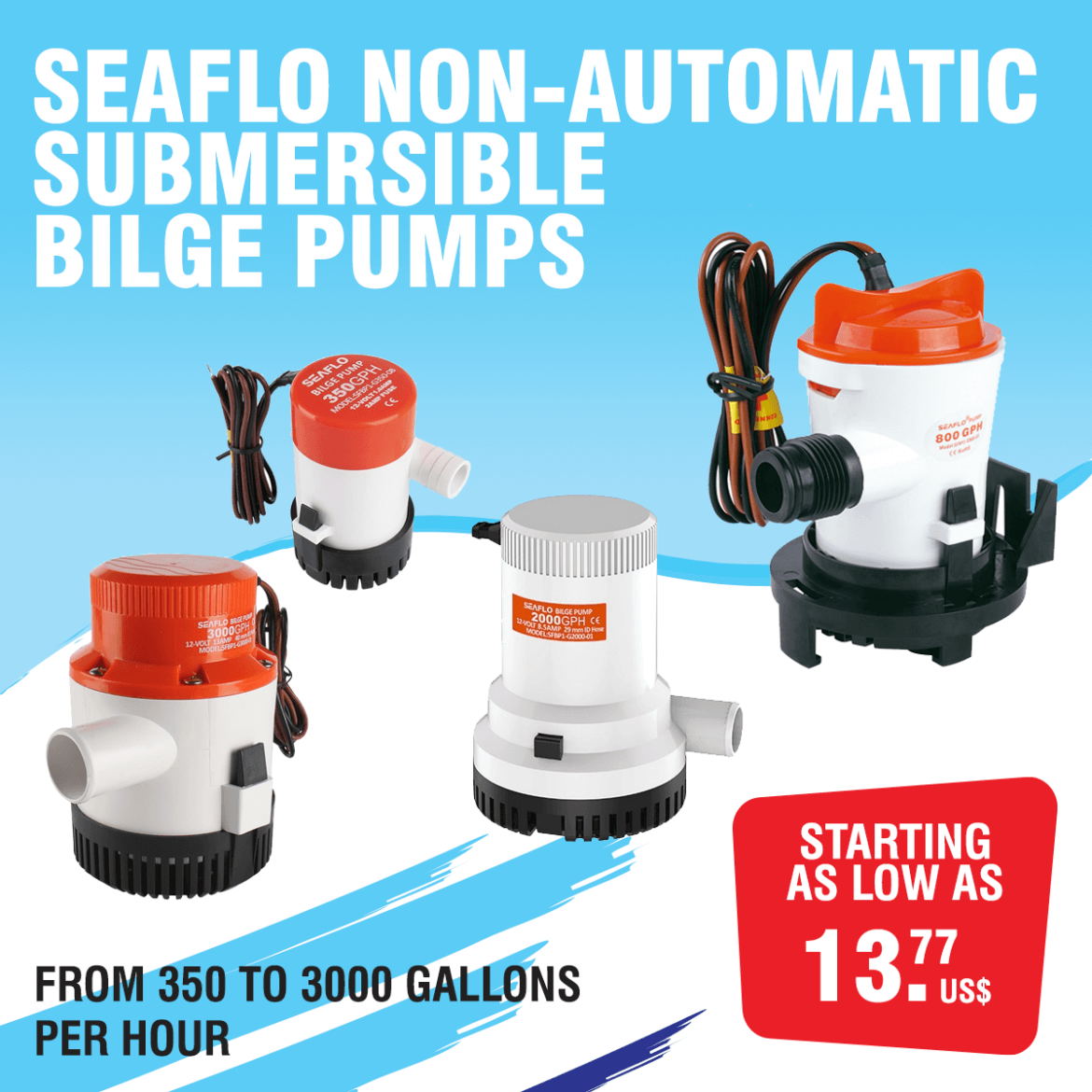

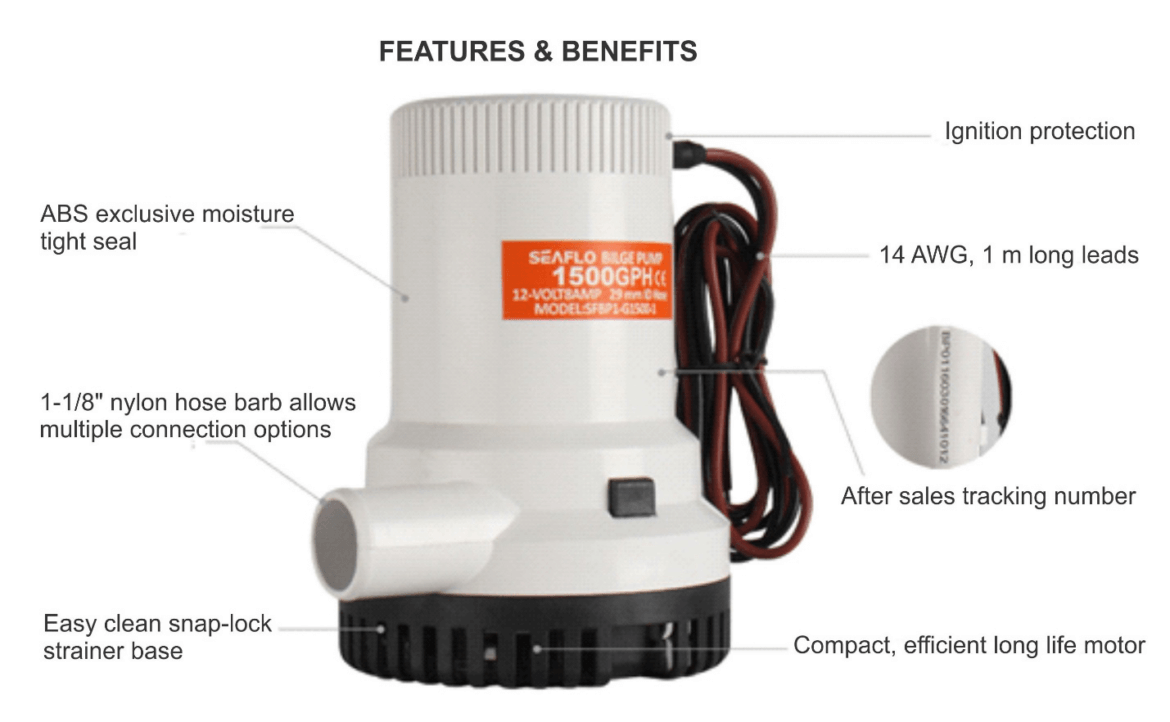

SEAFLO offers quality, robust bilge pumps in 12-volt and 24- volt models at a great price, using new technologies and integrating enhancements such as low amp draw, premium flow, ease of installation and maintenance-free designs.

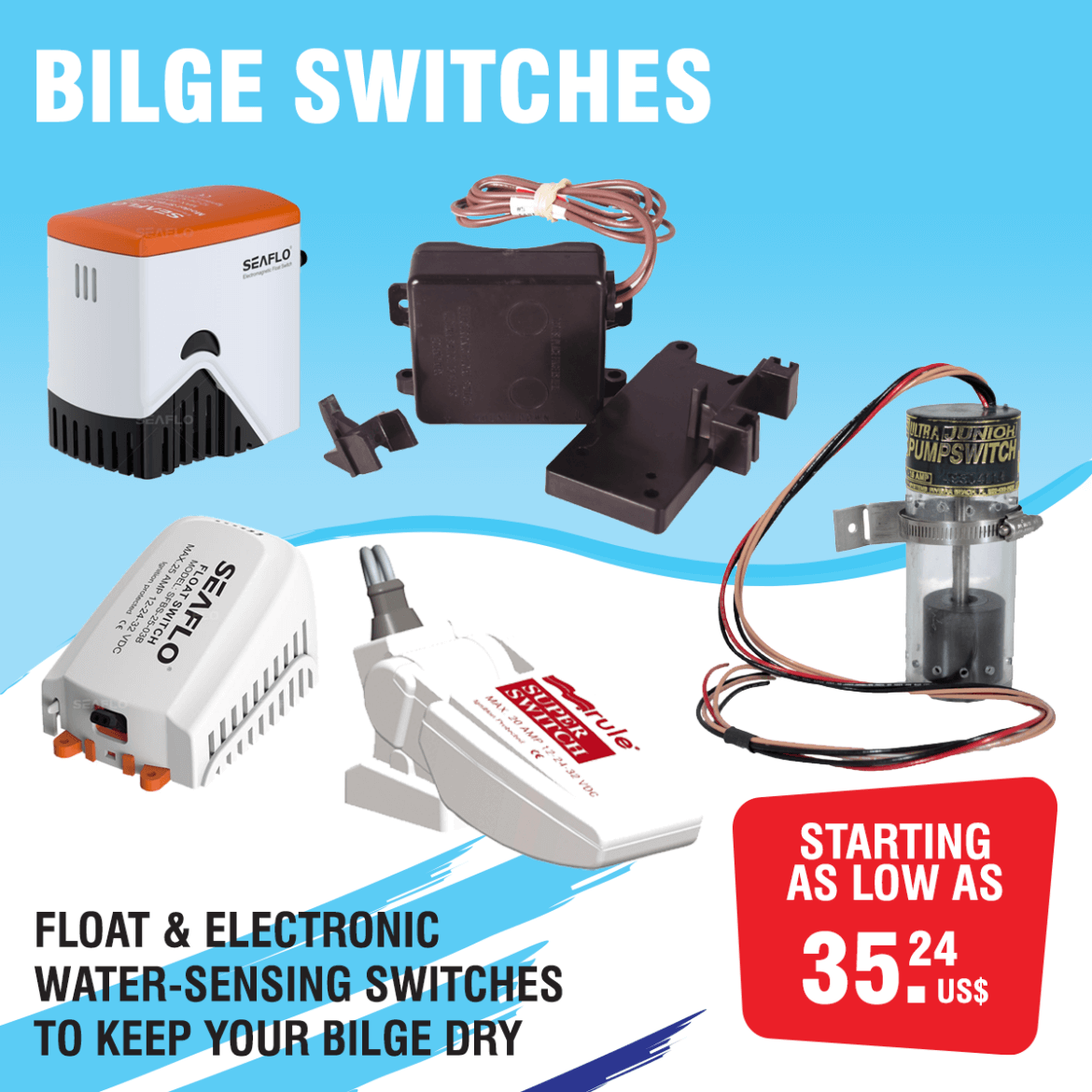

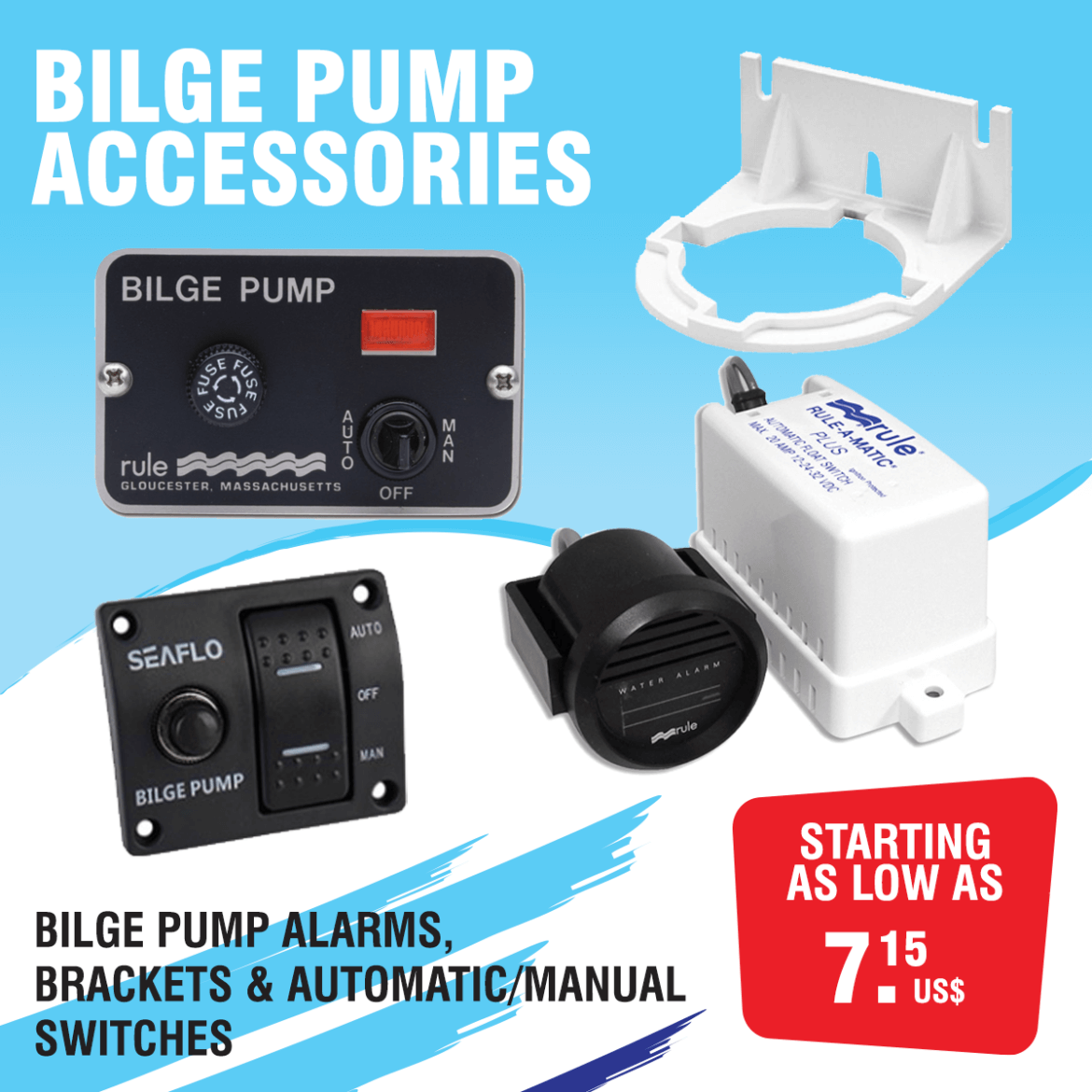

Non-automatic bilge pumps must be turned on when you need to drain the bilge. If your boat is equipped with one of these, be sure to turn it off once the bilge water is gone. Even if your pump model can run dry without seizing up, it may drain the battery if left on too long. The addition of a separate Bilge Switch is a practical solution to this problem.

Float switches consist of a hinged float that completes a circuit to energize the pump when bilge water rises. Formerly liquid mercury was used to complete the circuit, but environmentally safe switches have taken their place.

Electronic water-sensing switches use detector cells that sense the presence of water through the plastic housing, using a low-impedance electrical field. This totally sealed switch has no moving parts.

For safety, it is advisable to install a second back-up bilge switch in case the primary one fails.

Automatic bilge pumps use an integral float switch to activate the pump once water pools above a predetermined level. Once the bilge is free of water, the switch deactivates the pump. This feature prevents the bilge pump from running constantly while also protecting the boat from built-up water.

The slight downside is that de-clogging the float switch may be more difficult when it is integral to, rather than separate from, the pump.

Manual bilge pumps are vital for safety and should be strategically placed for ready access when really needed.

A catastrophic hole in the hull from collision or storm damage calls for very large pumping capacity. Even the largest pumps will probably only buy you a little time to effect repairs, limp to shore, or prepare to abandon ship. For emergency situations like this, it is advisable to have multiple electric pumps and at least one high-capacity manual diaphragm pump, such as a double-action hand pump.

Bilge alarms enhance water control by alerting the crew with sound and light.

3-way switch panels with rocker and toggle switches have a spring return from the “manual” to “off” position, to prevent leaving the pump running by accident.

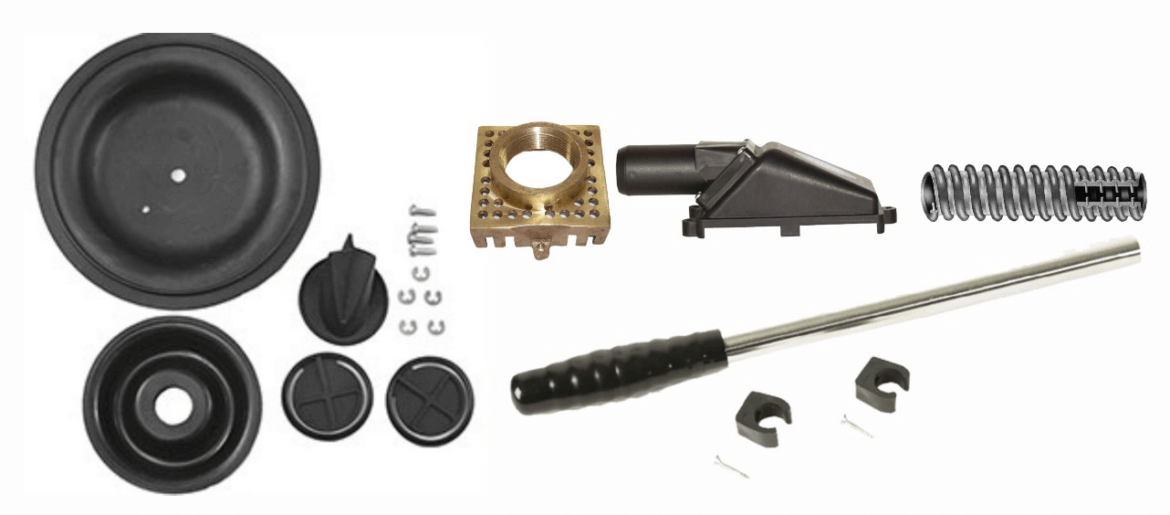

Pump handles, strainers, hose, impellers, and service kits for bilge pumps are also stocked.

Epifanes Bilge Paint is a protective paint based on a modified alkyd resin. The paint can be used in bilge spaces & engine rooms where a tougher paint system is required. It can be applied over most substrates with one component primer systems.

Interlux Bilgekote is a fast drying, durable coating formulated for application to bilge areas above the waterline. It helps prevent absorption of oil, gasoline or sludge into wood and fibreglass and cleans easily.

Interprotect is a high performance two pack primer/undercoat. It’s perfectly formulated for polyester, vinylester, epoxy, steel, aluminum, ferro cement and timber hull, above and below the waterline.

Bilge Pump Maintenance is critical for your safety and can reduce costly pump replacement and boat repairs caused by flooding.

Test bilge pump functioning by pouring water into the bilge and observing its removal. Clean the pump to clear unwanted algae, debris, and dirt. Use bilge cleaners that break down built-up sludge and encourage smooth running. Remove debris build-up from filters that may overwhelm the pump.

If you hear the pump running constantly, check for corroded wiring or a clogged float switch. If neither is faulty, check for other causes of excess bilge water. If only a small amount of water comes out of the bilge outlet, inspect the hose for damage and clogging. Check impeller rotation on centrifugal pumps by shutting off power to the pump and seeing if it turns freely by hand.