“Which sealant/adhesive should I use for this application?” This is a frequently asked question from first-time boatowners and even experienced contractors, who find the vast selection of available products daunting.

Here are pointers for selecting adhesives, bedding compounds and sealants – but as always, please read manufacturer instructions carefully re suitability, preparation, and temperature/humidity factors that affect curing.

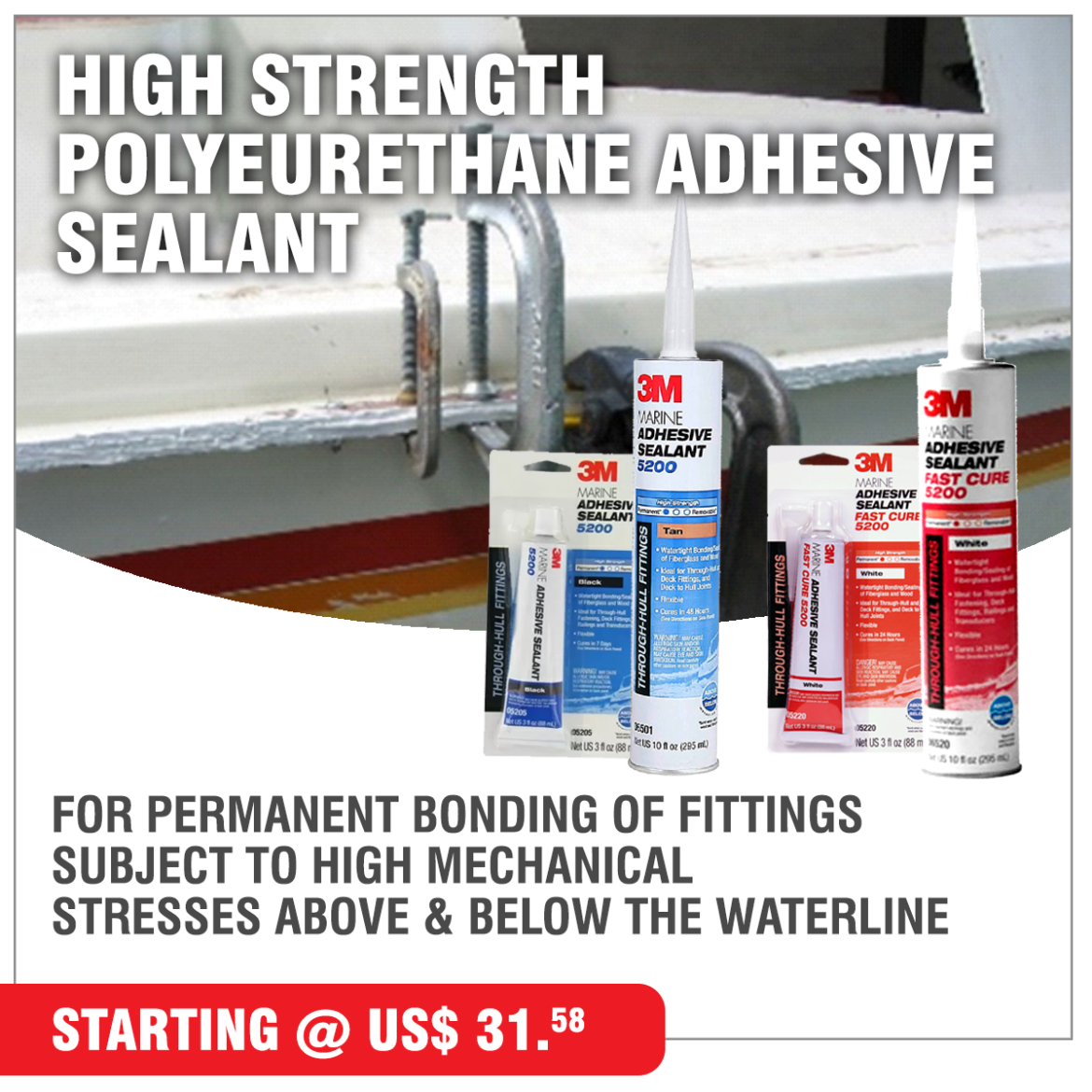

Polyurethane (PU) compounds are often used to join GRP hulls and decks together, and bedding keels to hulls, but like polysulphides, they should not be used on certain plastics.

3M 5200 forms a watertight seal and strong adhesion to wood, gelcoat, and fiberglass. It is flexible, allowing for movement and stress dissipation. Fast Cure 5200 becomes tack-free in 1 hour, fully cured in 24 hours. However, if parts need to be separated in future, don’t use 5200. When 3M says its product is permanent, they mean it!

These general-purpose PU adhesive sealants provide good adhesion to wood, fiberglass, gelcoat, metals, and some plastics. They form a watertight seal on joints and boat hardware above and below the waterline, can be sanded and painted, and with some persuasion, can be removed when necessary.

Surface cleaning and preparation will make or break the use of these products. When a primer is recommended it should be used, as it can improve adhesion by 20%. SIKA’s pre-treatment guide can be found at:

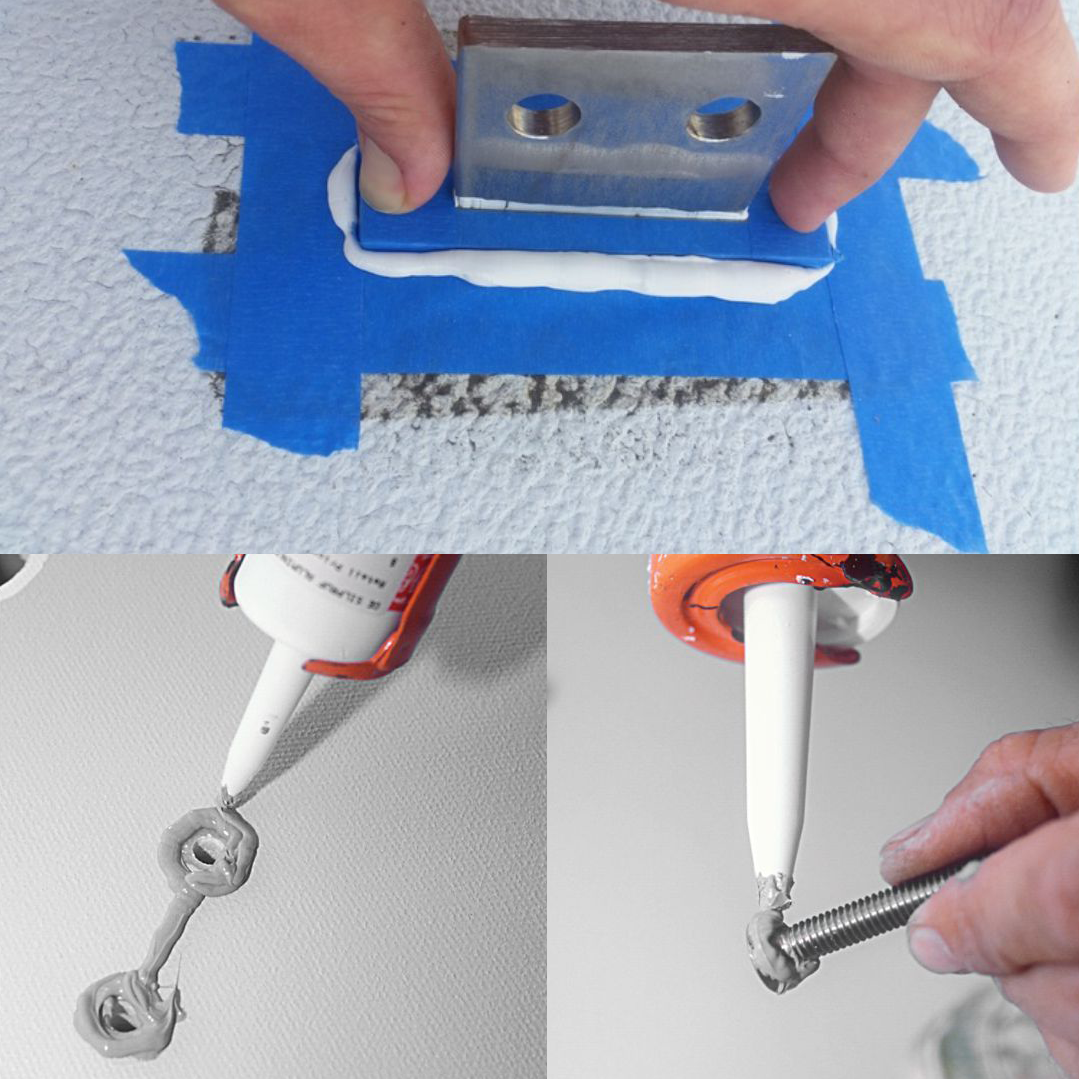

Always apply a generous amount of sealant to the fitting and to the surface holes into which the fitting will be inserted to fill all voids.

Sealant shelf life once opened is short – so don’t leave an open tube hanging around without a full nozzle, and only buy the size tube required for the job.

Silicone is an inert, synthetic polymer. Unlike adhesive sealants that mechanically bond to certain materials, silicone is a non-adhesive sealant that works like a flexible waterproof gasket and will generally rely on the aid of a fitting, screw, or bolt to create a waterproof seal and hold everything in place.

Silicones work especially well in sealing/securing glass, metal and some plastics and have excellent UV characteristics. They also have a longer shelf life, both opened and unopened, than the products which cure from atmospheric moisture. However, they are not for use below the waterline, and cannot be painted, so residue may be difficult to disguise.

These flexible hybrid sealants have the durable bond strength (and in some cases the paintable properties) of a polyurethane adhesive sealant, while also having the superior weathering and UV resistance of a silicone sealant. They are extremely versatile and suitable for both sealing and bonding across a range of materials (wood, metal, fibreglass) above and below the waterline, reducing the need for multiple products for every different application.

3M™ Weatherban™ Sealant Tape features an aggressively tacky, solid extrusion that offers a strong hold for many sealing applications, such as sealing between glass, metal, wood and many plastics. Permanently tacky, it has exceptional cold flow resistance and low moisture vapor transmissions, acting like a compressed grommet as well as an adhesive seal.

Weather resistant and easy to compress or reshape, it will stay in place when positioned vertically, overhead, or around sharp corners. It acts like chewing gum and does not go off quickly, so misplaced/surplus material can be removed and kept for future use.

Polysulphide is a synthetic rubber commonly used for caulking as it forms a strong bond and can be sanded and painted once fully cured. As a bedding compound it allows for movement yet grips tenaciously to both surfaces, working especially well for underwater wooden boat seams. It has excellent resistance to UV, fuel, and oil, makes a great electrical insulator, and is resistant to vibration, shock, impact, and thermal changes. It may be applied underwater in an emergency.

Not be used with plastics (especially acrylics – Plexiglas, Perspex) as it contains solvents that can make them brittle. It will also attack PVC and ABS, but not nylon.

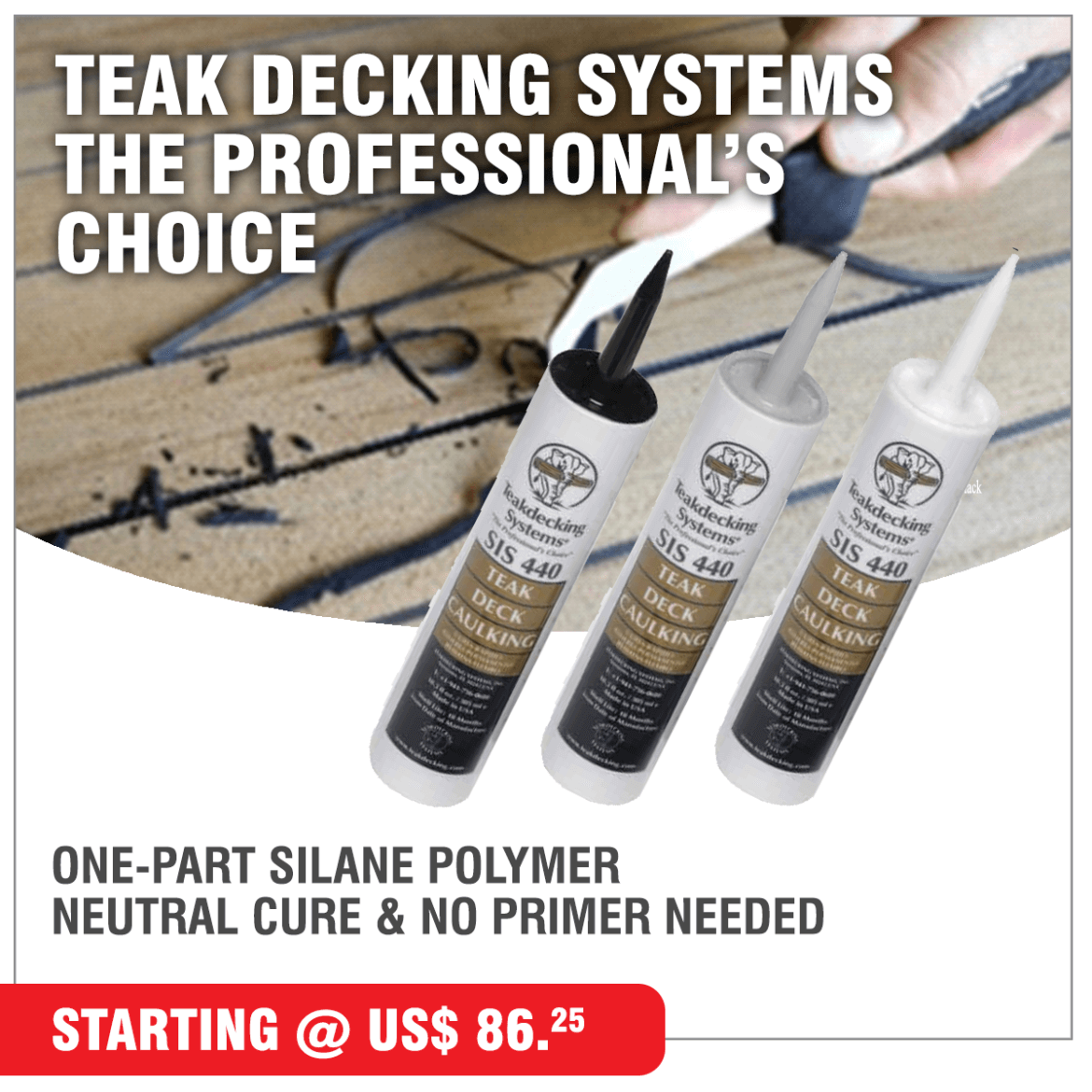

TDS Deck Sealant is a one-part, paste-like neutral cure system which, when exposed to moisture in the air, reacts to form a tough, flexible solid rubber compound. The sealant is thixotropic, does not sag during cure, and, when cured, has excellent temperature stability and chemical resistance. It is easy to sand and has an 18-month shelf life.

For very clear instructions on how to re-caulk old seams go to:

Nitrile gloves are a good choice for use with most adhesive products. Don’t use Latex gloves through which chemicals can leach and become trapped against the skin.

Wash your hands with soap and water – rather than solvents/sanitizers that contain alcohol that can open the skin to whatever chemical you are trying to wash off your hands.

If looking to bond something onto a surface, aim for a triangular bead that flattens evenly when compressed.

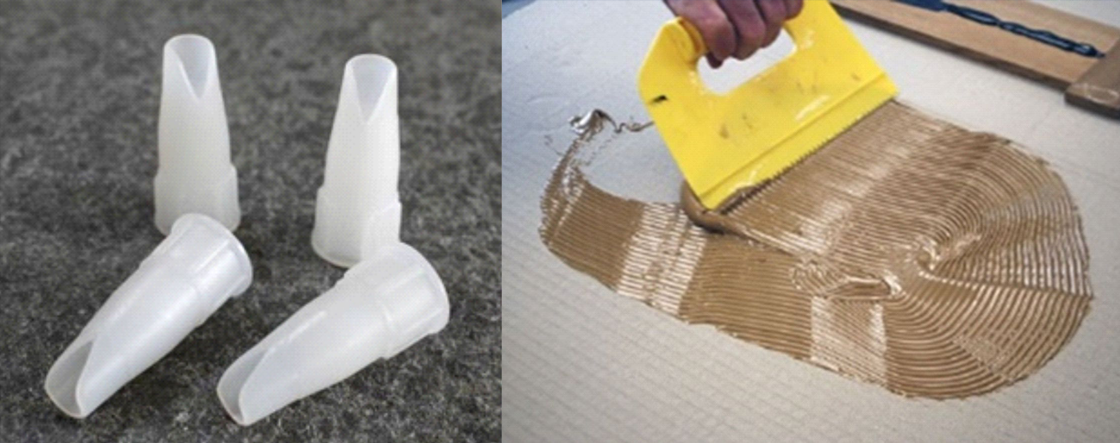

Cut a V shape in the nozzle and apply with the gun perpendicular to the surface, keeping consistent pressure on the trigger.

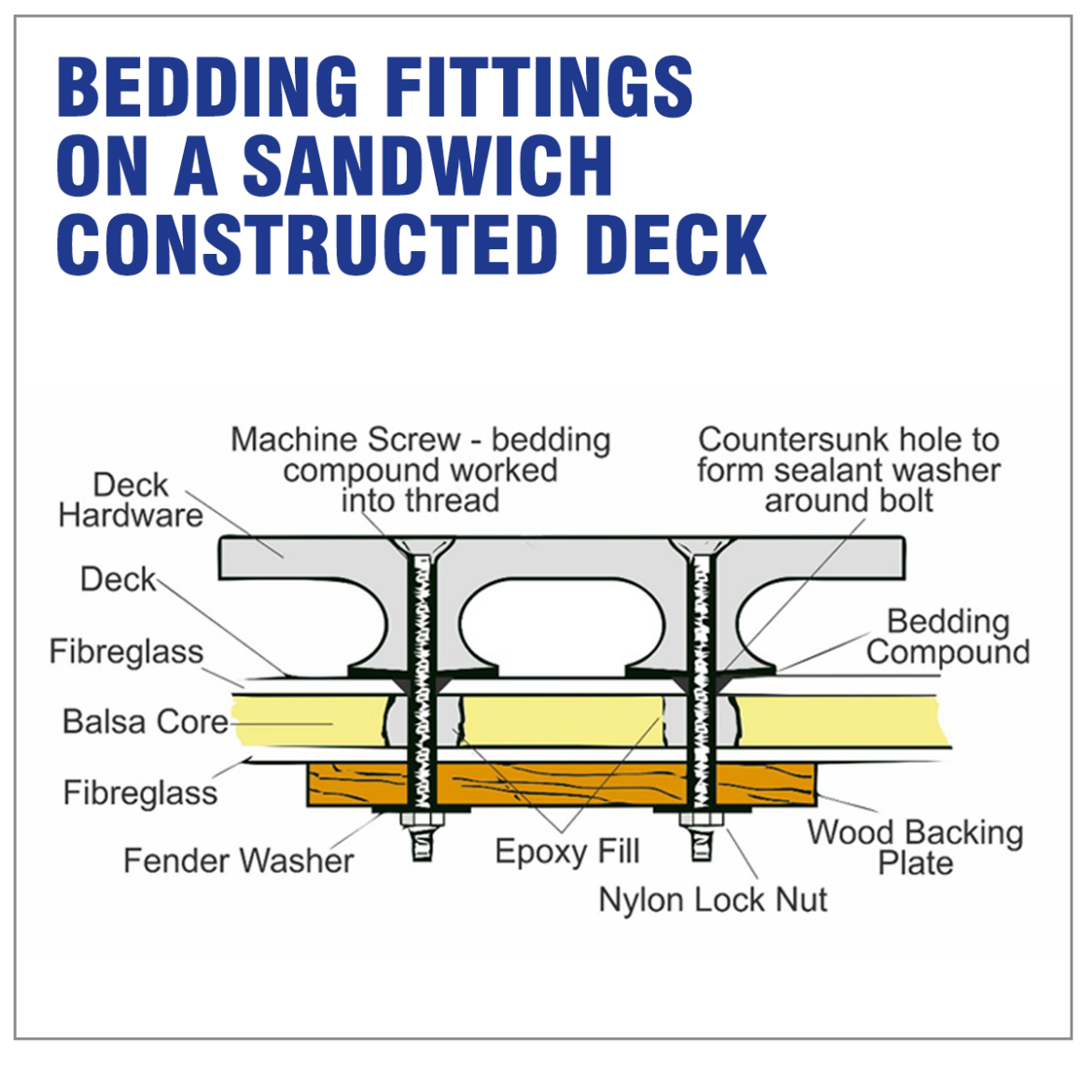

Don’t fully tighten deck fittings during application – screw/bolt them down almost tight and once cured give final tighten to compress sealant and bed down securely. Tighten the nut and not the bolt with this final tighten.

Lay bedding compound with a notched spreader to ensure an even spread