Dear Customer,

When handling fuel onboard, caution is the watchword. Hazardous fumes, accidental spills and blocked fuel lines are serious matters that threaten safety, create mess and result in significant financial liability. This Technical Corner has product information and safety tips to assist you.

What does a fuel separator do?

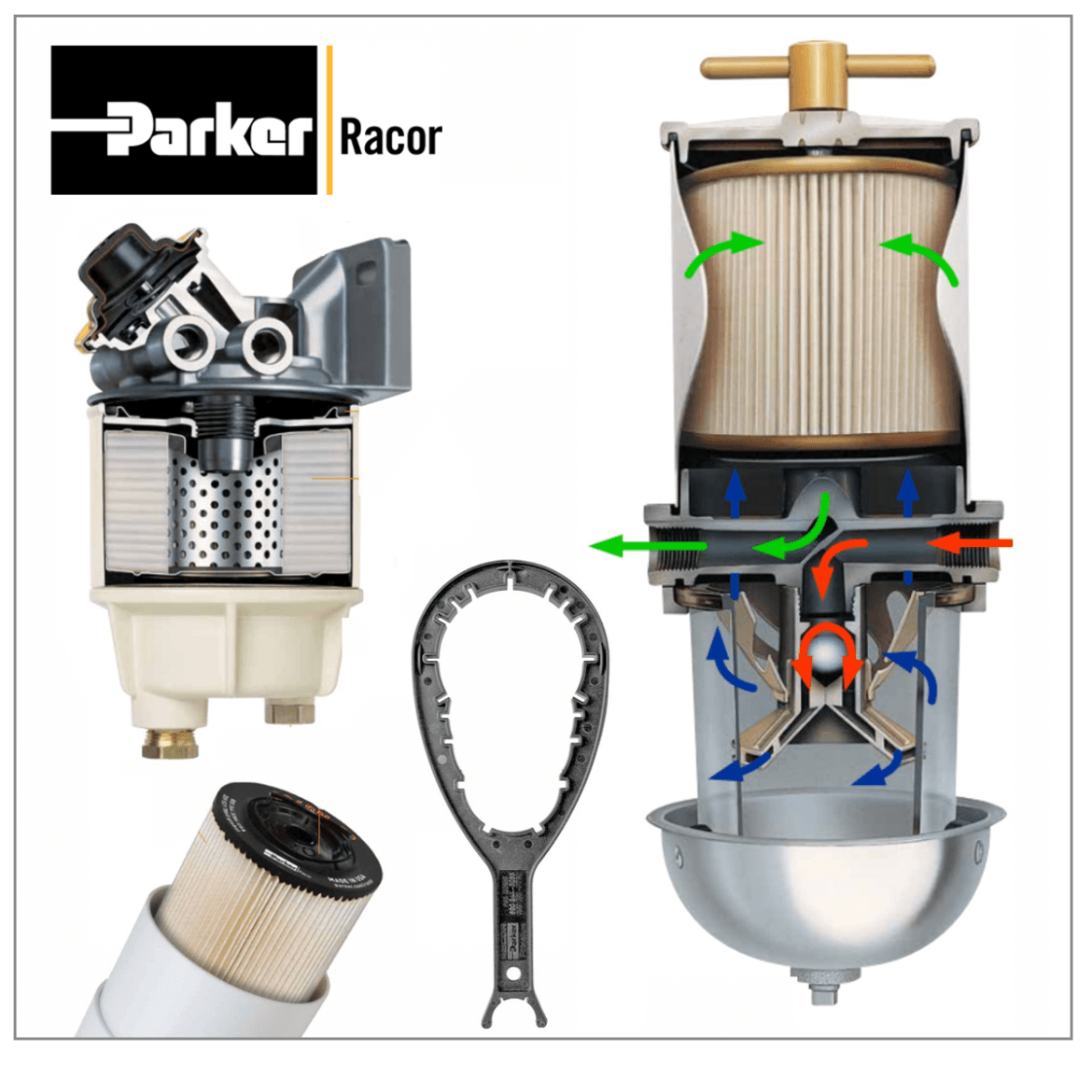

A Fuel/Water Separator filters out any impurities such as water from your fuel before it goes into the engine. The filter unit is positioned in the fuel line between the tank and engine at an easily accessible spot and consists of two chambers.

The first chamber is a centrifuge that spins the fuel at a high enough speed that denser impurities (in this case water) get thrown outside of the centrifuge and deposited into a collection bowl below the separator.

After the centrifuge, the fuel moves up through the second filter chamber in which the filter removes all other particulates that can decrease the performance of the engine. The filter media of this chamber comes in several porosities, rated in microns. The smaller a filter’s micron rating is, the greater its ability to trap contaminants.

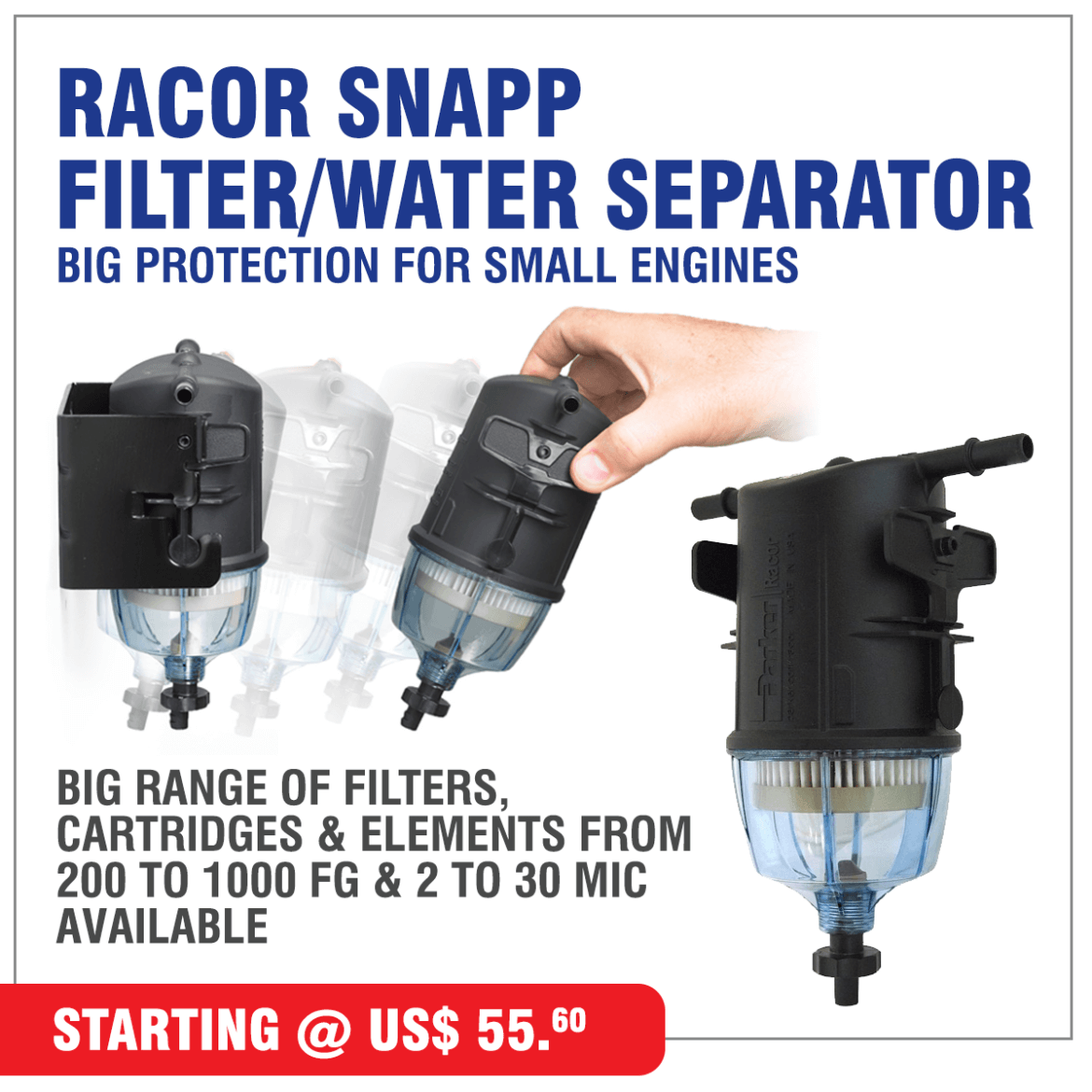

SNAPP is a compact, easy-to-service, fuel filter/water separator designed for use in mobile and stationary gasoline and diesel engines. Its patented bracket and quick connect system fittings eliminate the need for threads or seals, making change-outs quick, clean, and painless, without the use of tools.

Suitable for E10 gasoline, diesel and bio-diesel applications with fuel flows up to 40 gallons per hour.

Factors to consider when selecting the right separator

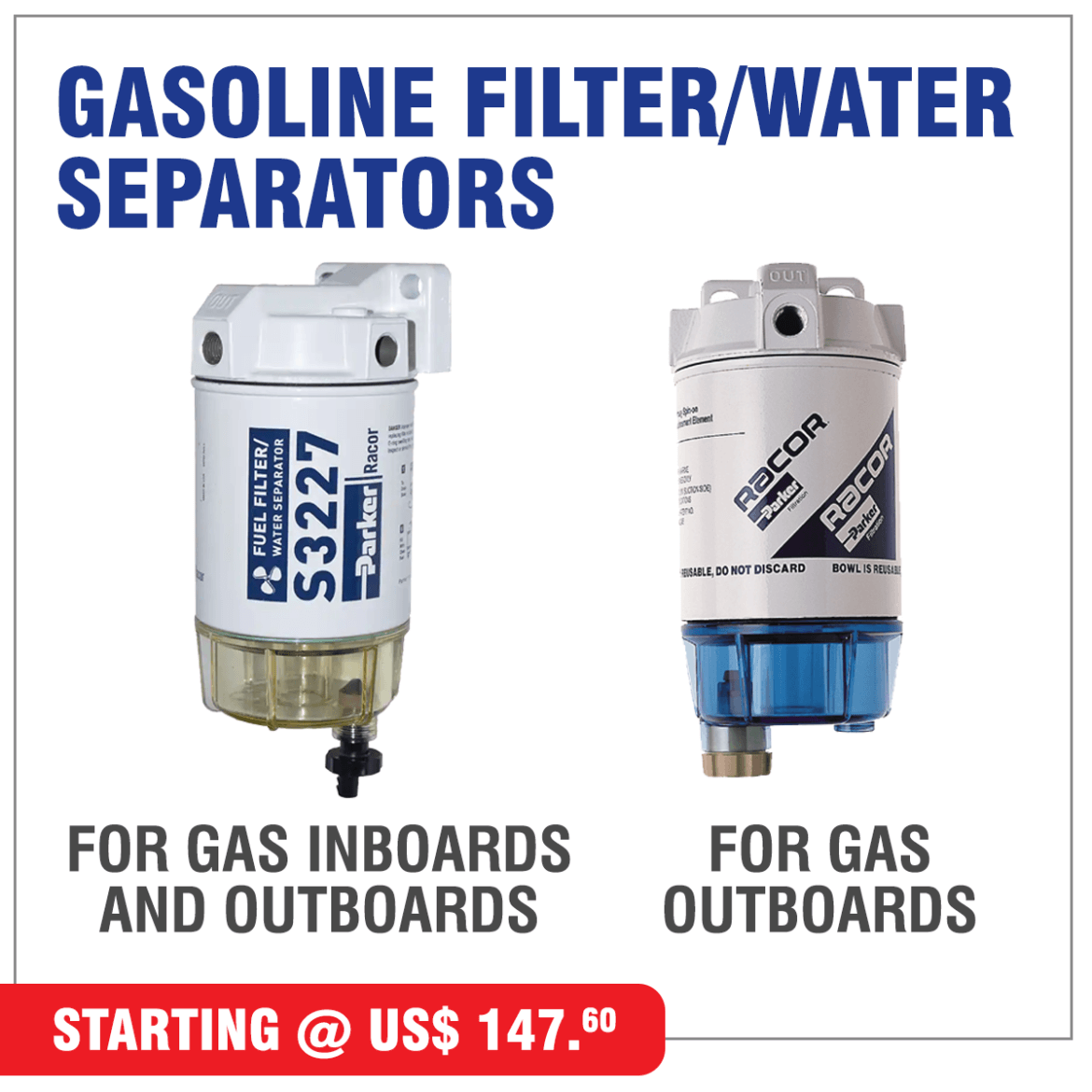

The filter comes in a variety of porosities (state of being porous): 2, 10, or 30 microns. For most boats, 10 microns is enough, but some sensitive systems can use a secondary two-micron filter installed farther down the line.

The inspection bowl, into which the water from the centrifuge chamber drops, comes in aluminum, clear heat resistant plastic, or a combination of both. Clear ones make it easy to see when you need to drain the bowl – you don’t want to let the water overflow.

Fuel flow rate (Gallons per hour/Litres per hour) is the most important factor. You’ll need to know the specifications for your particular engine model to know which separator to choose.

It is good practice to have a manual inline shut off valve, traditionally just in front of the fuel water separator, to cut off fuel to the engine for any safety reason.

PARKER RACOR has been the most trusted name in engine protection for many years. Their fuel filtration systems have earned the confidence and respect of engine builders, owners, and operators around the world. Leading edge technology and continuous innovation are designed into every system. Refer to their informative website for full product details:

Davis Instruments universal deck plate key is a handy pocket-sized tool that fits all deck plate caps, such as slotted, raised lug, spaced hole, and star (winch handle) type caps. The tool also has common hex sizes: 5/16″ (8 mm) for hose clamps and 7/16″ (11 mm) for 1/4″ (6 mm) bolts. Other features include a shackle key, flat screwdriver, and bottle opener.

Avoid losing this essential item, either onboard or overboard. Put it on a lanyard with a cork floatation device and keep it in an accessible place for quick retrieval. This way you can hang it round your neck while working on deck or monitoring the fuelling process.

Safety when filling:

Clear the area of anyone not directly involved with fueling the boat.

Turn off engine and electronics and extinguish all open flames/smoking materials.

Keep the nozzle in contact with the edge of the fill to prevent build up of static electricity to prevent sparking.

Don’t top off your tank. Know how much fuel your tank holds and fill it to about 90%. Fuel expands as temperatures rise.

Clean up fuel spills immediately with an oil-only absorbent pad. Wipe down the bilge or any interior parts that may have come in contact with fuel.

Never use hands-free clips or props to keep the nozzle in place. Hold the nozzle and avoid any distractions while fueling.

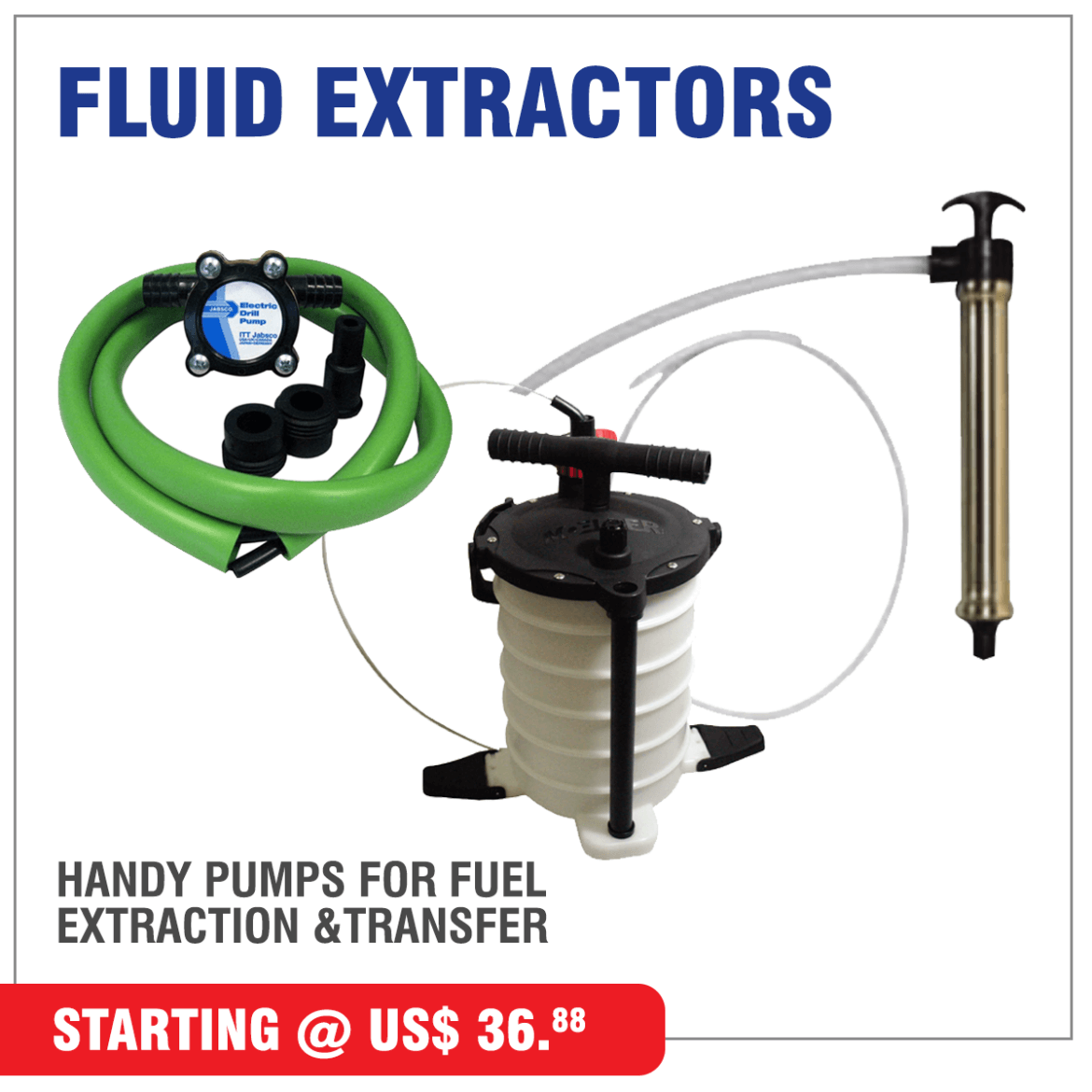

Fuel Polishing is pumping all the fuel out of your fuel tank(s), running it through a filtration system to remove water and debris and putting it back in the tank. Some professional services also clean the tank while it’s empty.

If your boat has been sitting for a while in a hot, humid climate, you may need to polish your fuel to remove water, microbes and other contaminants before they harm or stall your engine. While filters and biocides help, they can only do so much. The build-up of water and sludge at the bottom of your tank can block the flow of fuel just as you’re entering a tricky place, causing damage to your engine and the property of others.

Your fuel will likely need polishing:

- When your boat has sat for a while in a humid climate

- If you buy a second-hand boat that hasn’t been used recently.

- If a fuel cap was loose and water/dirt may have entered the tank.

- If someone confuses the water and fuel fills – yes, this happens!

If you discover an abnormal amount of water or debris in your filter

If you have a large volume of questionable fuel on board that can be cleaned, rather than dumped

Before going out in “boisterous” conditions that could stir up the water and debris

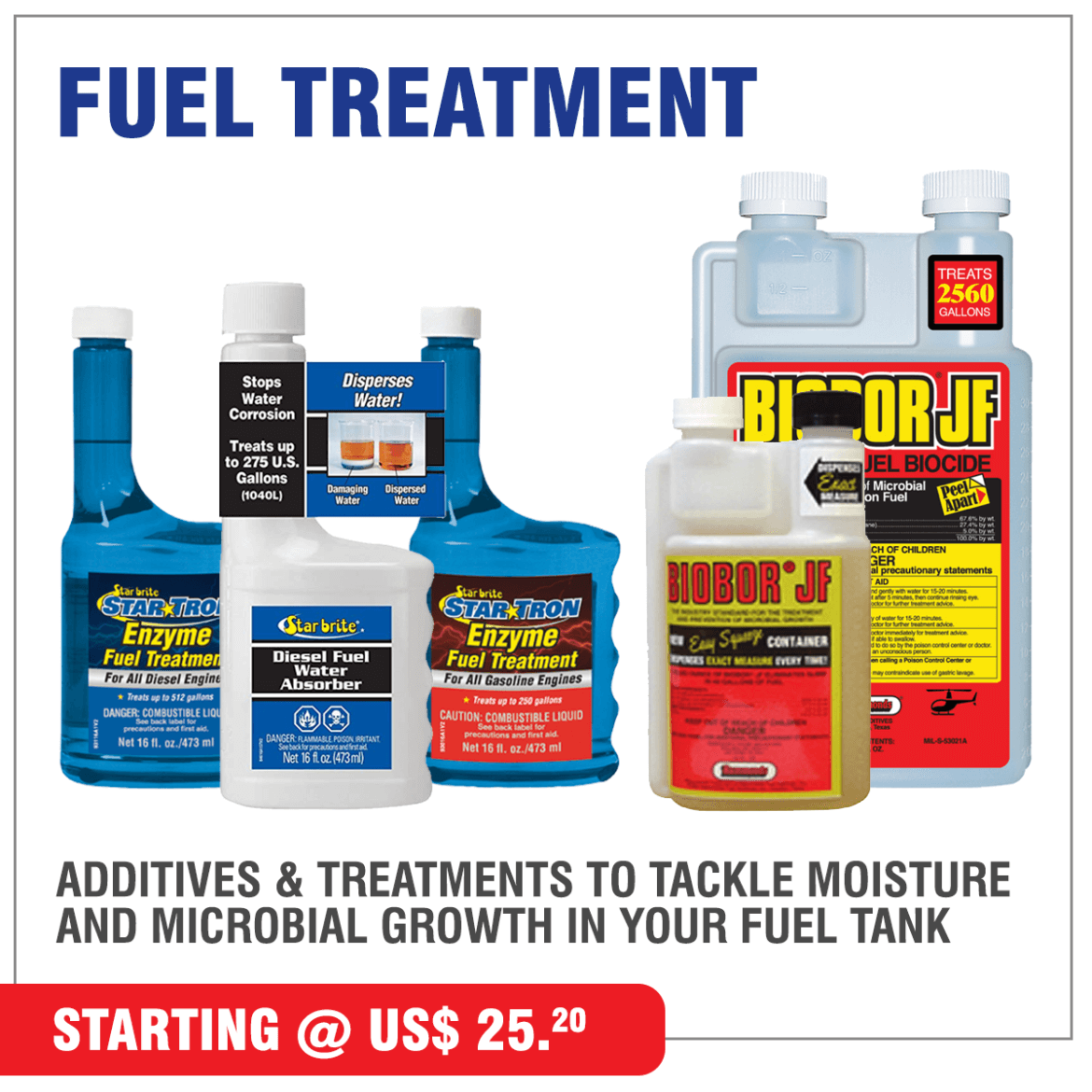

STAR TRON ENZYME FUEL TREATMENT uses enzyme technology that allows all engines to start easily and run smoothly, even after sitting idle for months. By breaking down excess water and sludge to sub-micron size, and allowing it to be safely burned away during normal engine operation, it tackles fuel issues as follows –

Helps increase fuel economy

1 fl. oz. treats 32 gallons of diesel fuel

Makes engines start easier, run smoother

Cannot be overdosed

Disperses moisture

Reduces all emissions, including carcinogenic, particulate smoke – eliminates diesel soot

Stabilizes diesel fuel for up to two years

Lowers fuel system maintenance

Eliminates carbon build-up from burners, injectors, and exhaust components

BIOBOR JF, one ofthe most widely used and recommended fuel biocide and lubricity –

- Kills microbial growth in all fuels

- Adds lubricity to ultra-low sulphur diesel fuel, protecting injectors and fuel pumps

- Prevents clogged filters

- Prevents corrosion

- Kills in both water and fuel phase