Propane (LPG) is heavier than air and the crew aboard two boats destroyed by a gas explosion had no idea the gas was in the bilge.

The first explosion lifted the boat’s entire deck almost a foot in the air; remarkably, the crew who unknowingly lit a cigarette, lived to tell the tale. The folks involved in the second incident weren’t so lucky.

In the past many long-distance sailors recommended kerosene/paraffin stove for safety and that’s what we installed on our first boat. Kerosene, when we could find it, wasn’t always of the best quality and so the jets in the burners often blocked. By turning the control knob a certain way, a pricker cleared the jet. The prickers often broke and we ended up not only carrying spare prickers, but entire burners to keep the thing going. To light the stove required preheating the burner with methylated spirits, and if you failed to heat it enough clouds of smoke and unburned kerosene decorated the headlining above the stove. Lighting the thing in a seaway, while inhaling half-burnt kerosene and black smoke, called for a strong stomach. We managed some relief when another sailor with a similar stove told us we should be running ours on jet fuel, and he was right, however, sourcing the stuff was a challenge. My wife and I traveled miles in search of small airfields prepared to sell us a jug of jet fuel. Something that’s probably impossible today.

Our first propane stove was a gift from heaven but rekindled all our fears about safety.

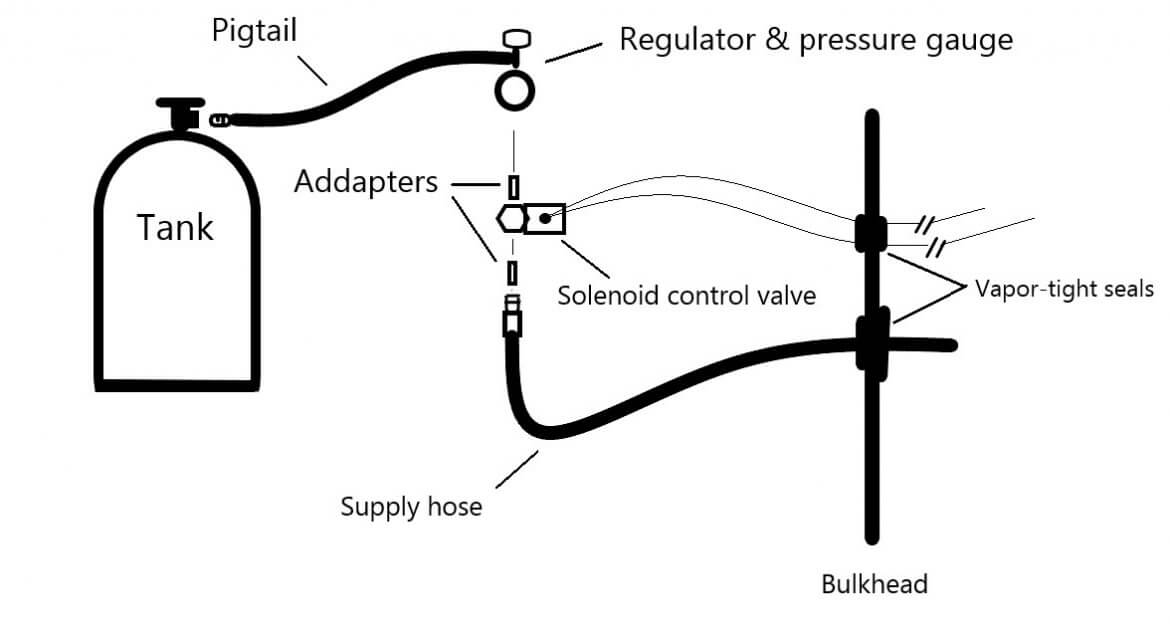

In a perfect world propane tanks should be housed in their own sealed locker complete with overboard drain (not shown on drawing). Perhaps it’s just the strange boats that I have owned but I have never had one with a sealed locker or found the room to construct such a thing.

One answer is to stow the propane tanks outside and weatherproof the fittings. This works but it usually means running long lengths of pipe through the boat.

If your tanks are in a sealed locker then where the pipe(s) and solenoid wires exit the locker they must pass through vapor-tight seals or you defeat the object.

While copper pipe is still used in some propane installations, flexible pipe, supported every 18 inches, is a much safer option. Note that while propane hose is only carrying 0.5 psi, they have a 350 psi working pressure rating, making them dramatically stronger than they have to be.

Propane detectors/sniffers/alarms are now found on most boats and if your boat doesn’t have one then I recommend you install one. Detectors can be basic or come with an array of sophisticated bells and whistles but they shouldn’t be a substitute for the skipper regularly carrying out a leak test on the propane system.

Checking the system

Operate the stove, then close all the burner valves, but leave the solenoid switch on. Read the pressure gauge, then turn off the manual valve on the tank. After five minutes, read the pressure again. If it is unchanged, wait 15 minutes and read it again. Any drop in pressure indicates a leak that must be located (with soapy water) and fixed. Note: The pressure gauge does not tell you how much propane is left in the tank. The pressure gauge is to allow you to easily — and frequently — leak test the LPG system.

The soapy water test

Make sure the valve of your propane cylinder is closed.

Mix one part dishwashing liquid soap to three parts water in a bowl or a spray bottle, then soap up the entire hose assembly including the valve and regulator.

Brush, or use a sponge to soap the connections.

Make sure the controls of the appliance are in the off position, then slowly open the cylinder valve. This pressurizes the system.

If you see bubbles then you have a leak.

Good practice

When you are through cooking, leave one burner ignited and turn off the solenoid. When the burner goes out, close the burner valve. This empties the line of gas so that none will leak into the bilge should a burner valve fail to seal.

If you will leave the boat unattended for a while, it’s best to close the valve on the tank to eliminate all risk of undetected leakage.

Sniffer alarms should be placed as low as possible and tested regularly following the manufacturer’s instructions.